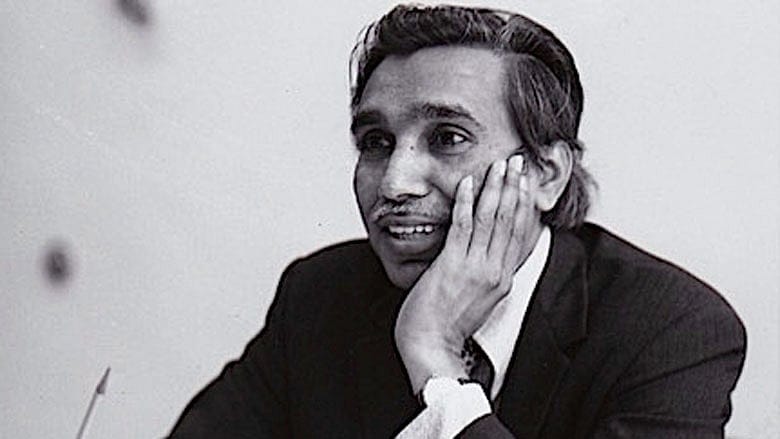

The revolutionary skyscrapers of Fazlur Khan

Gazing across the horizon from the top floor of a 100-story building is like touching the sky. But who would stand 1,000 feet in the air without the firm assurance that the structure beneath was securely fastened to the ground?

[perfectpullquote align="right" cite="" link="" color="" class="" size=""]"I put myself in the place of a whole building, feeling every part. In my mind I visualize the stresses and twisting a building undergoes."[/perfectpullquote]